Smart Labels

Taking Labeling Technology to the Next Level

Smarter and Interconnected Labels

Smart labeling is an integral part of tracking and tracing components and products through complex supply chains, manufacturing processes and distribution networks. Working in collaboration with our customers, we are committed to extending the functionality of rubber labels using integrated technologies, such as sensors for monitoring, preventative maintenance, failure prevention and diagnostics.

Rubber Labels is always looking for industry partners to accelerate the development of these new technologies. Contact us today to discuss your ideas and help us transform the connectivity, communication and performance of rubber products with intelligent labeling solutions.

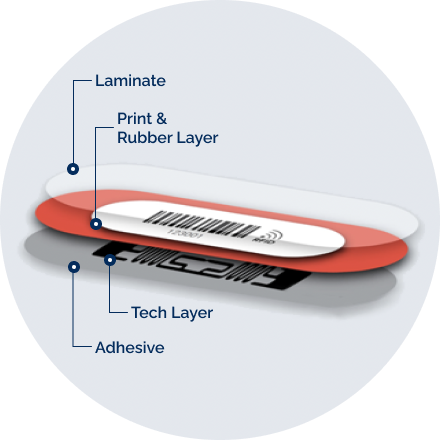

Breaking Down

the Smart Label

Based on their ability to co-vulcanize with the rubber substrates, rubber labels are ideal platforms to deliver innovative industry technologies — including integrated barcodes, QR codes, RFIDs and more advanced thin film technologies, such as sensing and communication.

We are continuously looking for partnerships to develop and commercialize new and advanced technologies in the rubber industry and beyond.

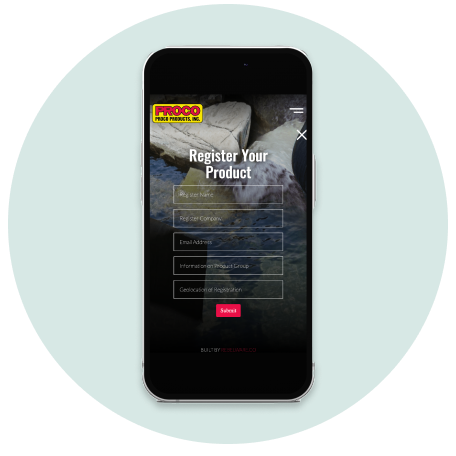

REEL-In by QRCode

Rubber Labels has partnered with Rebel Interactive Group to bring a revolutionary product to the rubber industry; one that has the potential to change the way rubber products are tracked, marketed and sold. Using our unique vulcanizable dynamic QR code labels and Rebel Interactive’s RebelWare technology, we are empowering product manufacturers to communicate directly with end-users to capture and control their data to monitor performance and generate future sales.

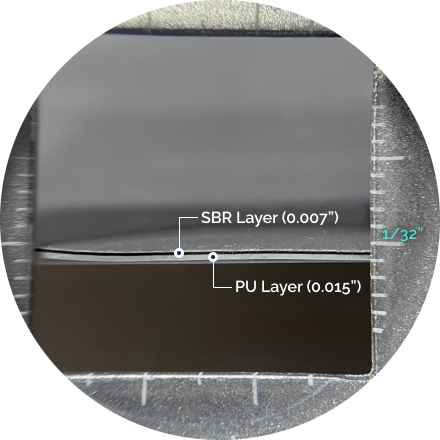

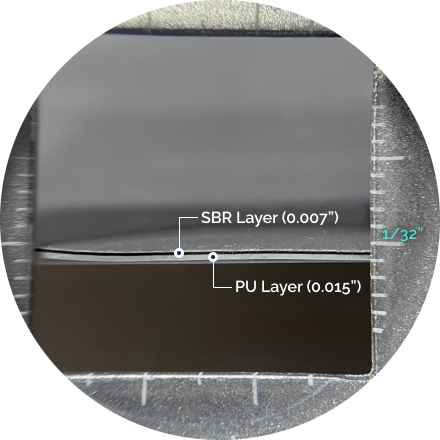

Vulcanizable and Printable Polyurethane Sheets/Rolls

Polyurethanes (PU) are known for their outstanding abrasion resistance and strength properties, which are important for applications such as conveyor belts for mining, footwear and more. Millable polyurethanes are often used for these applications, but their relatively high cost can be a disadvantage vs. general-purpose rubbers like SBR and NR. Co-vulcanizing a thin layer of the millable polyurethane over a general-purpose rubber gives a highly abrasion-resistant layer, resulting in improved performance and lower total cost compared to an all-polyurethane compound. Bonding of these dissimilar polymer types has been difficult in the past, but special formulation to either or both components has been found to result in excellent adhesion.

Rubber Labels has partnered with TSE Industries to combine our thin gauge calendering capabilities with TSE’s compounding and testing capabilities and we are currently commercializing layered PU/rubber sheets and rolls with a combined gauge as small as 15 mil (.38mm). We have developed methods for printing on these PU materials to provide full graphic/marking service, similar to our rubber label products.

Need help with your project? Call 877-348-3795

©Rubber Labels USA 2024 | Digital Marketing by Rebellion Group